Page 83 - TÜREB Rüzgar Sanayisi Kataloğu 2020

P. 83

83

SCHAEFFLER

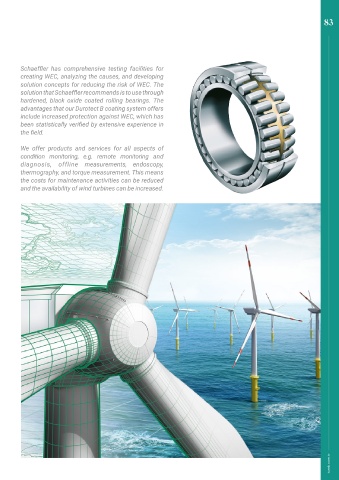

Schaeffler Çözümü Reliability made by Schaeffler Schaeffler has comprehensive testing facilities for

creating WEC, analyzing the causes, and developing

Optimize edilmiş rüzgar türbinleri, güvenilir çözümler Cost-effective wind turbines require reliable solution concepts for reducing the risk of WEC. The

gerektirir. components. As one of the world’s leading solution that Schaeffler recommends is to use through

manufacturers of rolling bearings and a development hardened, black oxide coated rolling bearings. The

Schaeffler her rüzgar türbinine yönelik doğru çözüm partner for the sector we have been producing advantages that our Durotect B coating system offers

ve güvenlik için entegre konsept sunar: bearing supports for wind turbines for over 30 years. include increased protection against WEC, which has

We offer the right bearing solution for every wind been statistically verified by extensive experience in

• Gelişmiş hesaplama ve simülasyon programlarıyla turbine and an integrated concept for safety. the field.

optimal tasarım

• Schaeffler Wind Power Standard We offer products and services for all aspects of

• Dünyanın en büyük ve güçlü rulman test donanımı • Optimum design with state-of-the-art calculation condition monitoring, e.g. remote monitoring and

olan “Astraios” ile gerçek koşullar canlandırılarak and simulation programs diagnosis, offline measurements, endoscopy,

yapılan testler thermography, and torque measurement. This means

• Realistic tests on Schaeffler’s ASTRAIOS

• Uzun çalışma ömrü sunan rulman çözümleri; the costs for maintenance activities can be reduced

örneğin, rotor milleri için optimize edilmiş oynak • Innovative solutions for preventing white etching and the availability of wind turbines can be increased.

makaralı büyük çaplı rulmanlar cracks (WEC)

• Sürekli kondisyon izleme özelliği ile artan çalışma • High equipment availability due to condition

süreleri

monitoring

With our highest quality standard for products and

processes we ensure optimum quality and reliability

worldwide, and provide the wind power sector with

quality standards that we have already successfully

established in the automotive and aerospace

industries. We work closely with our customers and

suppliers throughout the entire process chain to

ensure that our high standards are met.

Our specialists work in close cooperation with wind

turbine developers, manufacturers, and operators.

State-of-the-art calculation and simulation programs

ensure that optimum designs for bearings for wind

power applications are produced. The entire system

is considered, from individual rolling bearings

and their components and adjacent construction

through to the entire power transmission system,

which is displayed and optimized using multi-body

Adres / Address Saray Mah. Ömer Faik Atakan Cad. Yılmaz simulation programs developed in-house.

Plaza No:3 34768 Ümraniye / İSTANBUL

Tel. / Phone + 90 212 385 35 59 One of the world’s largest, most up-to-date, and

Fax + 90 212 284 32 48 most powerful large-size bearing test rigs enables

E-Mail [email protected] large-size bearings of up to 15 tons and with outside

Web www.schaeffler.com.tr diameters up to 3.5 meters to be tested. ASTRAIOS

Profil / Profile Rulman, gres, montaj - demontaj, kestirimci bakım simulates the real loads and moments that occur in

Bearing, gres, assembly / Deassemly, predictive a wind turbine. This means we are making a major

maintenance contribution to shortening development times for

Ciro / Turnover N/A

İstihdam / Employees - wind turbines, as well as making the design process

Yüksek Güvenilirlik

Kuruluş Yılı / Founding Year 1883 more reliable and increasing the cost-effectiveness tureb.com.tr

and safety of these turbines.

Schaeffler Çözümü

Optimize edilmiş rüzgar türbinleri, güvenilir çözümler gerektirir.

Schaeffler her rüzgar türbinine yönelik doğru çözüm ve güvenlik

için entegre konsept sunar:

• Gelişmiş hesaplama ve simülasyon programlarıyla optimal tasarım

• Dünyanın en büyük ve güçlü rulman test donanımı olan “Astraios”

ile gerçek koşullar canlandırılarak yapılan testler

• Uzun çalışma ömrü sunan rulman çözümleri; örneğin, rotor milleri

için optimize edilmiş oynak makaralı büyük çaplı rulmanlar

• Sürekli kondisyon izleme özelliği ile artan çalışma süreleri

Güvenilirlik: Schaeffler’in Rüzgar Gücü Standardı

Mühendislik uzmanlığımızı paylaşalım!

Yeni: Daha uzun çalışma ömrü ile

optimize edilmiş FAG rulmanları www.schaeffler.de/Windpower

913033_Windkraft_210x280_TR.indd 1 23.02.2017 11:36:30